ASME/ANSI B18.2.2 American Standard Hex Flange Nuts Manufacturer In China

Ningbo Teng Qi Fasteners is a manufacturers of ASME/ANSI B18.2.2 Hex Flange Nuts and we are committed to providing our customers with excellent quality and professional service. We have introduced advanced equipment, including cold heading machines and tapping machines, and equipped with an experienced technical team to ensure that our products have accurate dimensions and reliable quality.

We strictly control the selection of raw materials and use high-quality carbon steel and stainless steel materials to ensure that the products have excellent strength and corrosion resistance. The heat treatment process of the nut is strictly controlled to ensure that the nut reaches the required hardness standard and that its load-bearing capacity meets industry requirements. Flange nuts are available in a variety of surface treatment options, including blackened, galvanized and hot-dip galvanized, to meet different customer needs. We take customer satisfaction as our mission and provide customers with personalized solutions and high-quality products.

Strict inspection and testing are carried out in every process from raw material procurement to production process to ensure that the quality of the products is stable and reliable. In addition, we also focus on employee training and improve employees’ quality awareness and technical level to ensure that our products always meet customer requirements.

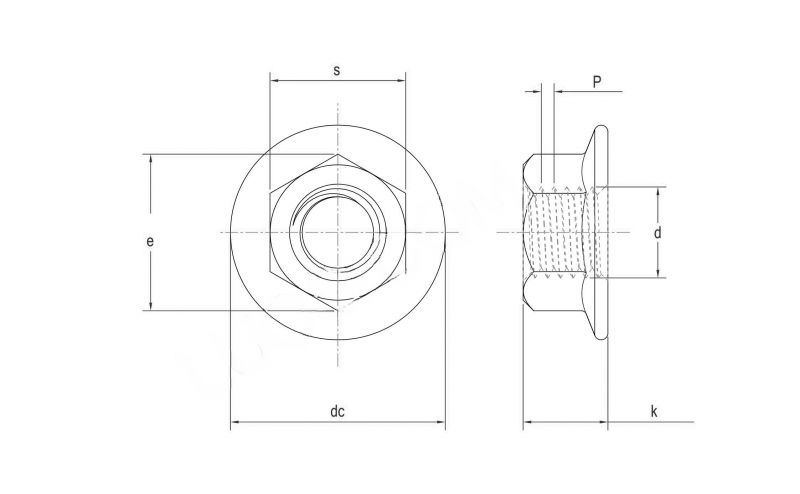

Specification of ASME/ANSI B18.2.2 American Standard Hex Flange Nuts:

The specification of ASME/ANSI B18.2.2 American Standard Hex Flange Nuts include the following details:

| Product name | ASME/ANSI B18.2.2 Hex Flange Nuts |

|---|---|

| Diameter: | #6-3/4” |

| Grade: | SAE J 995 GR.2/5/8 |

| Material: | Carbon Steel: Q195,Q235,ML08AL,C45,35K,40CR,42CRMO Stainless Steel: SS304/SS316 |

| Surface Treatment | Zinc Plated/Plain/Black Oxidation/Dacromet/Mechanical Zinc Plating |

| Packaging: | Boxes/cartons into wooden pallets |

Dimension Chart of ASME/ANSI B18.2.2 American Standard Hex Flange Nuts:

| Thread Diameter | #6 | #8 | #10 | #12 | 1/4 | 5/16 | 3/8 | 7/16 | 1/2 | 9/16 | 5/8 | 3/4 |

| P | 32|40 | 32|36 | 24|32 | 24|28 | 20|28|32 | 18|24|32 | 16|24|32 | 14|20|28 | 13|20|28 | 12|18|24 | 11|18|24 | 10|16|20 |

| s min | 0.302 | 0.334 | 0.365 | 0.428 | 0.428 | 0.489 | 0.551 | 0.675 | 0.736 | 0.861 | 0.922 | 1.088 |

| s max | 0.312 | 0.344 | 0.375 | 0.438 | 0.438 | 0.5 | 0.562 | 0.688 | 0.75 | 0.875 | 0.938 | 1.125 |

| e min | 0.342 | 0.381 | 0.416 | 0.488 | 0.488 | 0.557 | 0.628 | 0.768 | 0.84 | 0.982 | 1.051 | 1.24 |

| e max | 0.361 | 0.397 | 0.433 | 0.505 | 0.505 | 0.577 | 0.65 | 0.794 | 0.866 | 1.01 | 1.083 | 1.299 |

| dc min | 0.406 | 0.452 | 0.48 | 0.574 | 0.574 | 0.66 | 0.728 | 0.91 | 1 | 1.155 | 1.248 | 1.46 |

| dc max | 0.422 | 0.469 | 0.5 | 0.594 | 0.594 | 0.68 | 0.75 | 0.937 | 1.031 | 1.188 | 1.281 | 1.5 |

| k min | 0.156 | 0.187 | 0.203 | 0.222 | 0.222 | 0.268 | 0.33 | 0.375 | 0.437 | 0.483 | 0.515 | 0.627 |

| k max | 0.171 | 0.203 | 0.219 | 0.236 | 0.236 | 0.283 | 0.347 | 0.395 | 0.458 | 0.506 | 0.569 | 0.675 |

- RELATED NUT LISTS:

- DIN6334 Hexagon Coupling Nuts

- ASME/ANSI B 18.2.2 Hex Slotted Nuts/Castle Nuts

- Lock Nuts

- IFI145 Flange Nuts

- DIN982 Nylon Lock Nuts

- DIN985 Nylon Lock Nuts

- ASME B 18.16.6 Nylon Nuts

- HEX NUT

- JIS 1186 Hex Nuts

- DIN934 Hex Nuts

- A194 Hex Nuts

- A563 Hex Nuts

- DIN6915 Hex Nuts

- GOST 28919 Thick Hex Nuts

- GOST R 52645 Structural Hex Nuts

- GOST 5915 Hex Nut

- UNI5588 Hex Nuts

- UNI5587 Thick Hex Nuts

- UNI5713 Hex Nuts

- AS1112.1 Hex Nuts

- AS1252 Hex Nuts

- AS/NZS 2451 Hex Nuts

- AS/NZS 2465 Hex Nuts

- DIN6330 Hex Thick Nuts

- ASME/ANSI B 18.2.2 Hex Thick Nuts

Application of ASME/ANSI B18.2.2 Hex Flange Nuts:

ANSI/ASME B18.2.2 hex flange nuts find wide-ranging applications across various industries due to their specific design and functionality. Some common applications include:

| Application | Details |

|---|---|

| Automotive Industry: | Hex flange nuts are extensively used in automotive manufacturing and repair applications. They are employed to fasten components such as wheels, axles, and engine parts. The flange design provides a larger bearing surface, distributing the clamping force and reducing the risk of loosening, making them ideal for automotive applications where vibration and stress are prevalent. |

| Construction and Building: | In the construction industry, hex flange nuts are utilized for securing structural elements such as steel beams, columns, and frames. Their flanged design allows for easier installation and provides added stability, ensuring the structural integrity of buildings and infrastructure projects. |

| Machinery and Equipment Assembly: | Hex flange nuts are commonly used in machinery and equipment assembly, where they are employed to fasten components such as gears, pulleys, and bearings. The flange feature provides a built-in washer-like surface, reducing the need for additional washers and simplifying assembly processes. |

| Electronics and Electrical Equipment: | Hex flange nuts are found in various electronic and electrical equipment, including appliances, consumer electronics, and industrial machinery. They are used for securing components and mounting hardware, providing a secure and reliable connection in applications where space constraints may limit the use of traditional fasteners. |

| Railroad and Transportation: | In the railroad and transportation industry, hex flange nuts are utilized for securing rail tracks, signaling equipment, and infrastructure components. Their flanged design helps distribute the load evenly and provides a secure connection, ensuring the safety and reliability of railway systems. |

| Marine and Offshore Applications: | Hex flange nuts are employed in marine and offshore applications for securing components such as marine engines, boat hulls, and offshore platforms. Their corrosion-resistant properties make them suitable for use in harsh marine environments where exposure to saltwater and moisture is prevalent. |