Professional Bolts Manufacturer In China

Ningbo Teng Qi Fasteners Co., Ltd. is a enterprise specializing in the development and production of high-strength bolts. The factory is located in the Ningbo Industrial Park. It has more than 100 advanced production equipment and 30 years of production experience. We are one of the earliest professional companies in China to enter the fastener industry.

The company has advanced high-speed cold heading machinery and equipment and a fully automatic mesh belt furnace heat treatment production line. It mainly produces 4.8, 8.8, and 10.9 grade bolts and nuts, and 8.8 and 10.9 double heads. Order production of German standard DIN, British standard BS, American standard ANSI/ASME hexagonal bolts and nuts.

The company has been developing for more than 30 years. It has always focused on customer needs and won the trust and praise of domestic and foreign customers with complete and professional services. On the basis of insisting on innovation, the company strictly controls quality, pays close attention to detail management, and continuously improves The service level has achieved healthy development of the company’s business and has a good reputation at home and abroad. We always adhere to the business philosophy of “integrity-based, customer first” and adhere to the corporate purpose of “creating high-quality products and realizing value”, and have won the recognition and trust of many customers.

Type of Bolts:

Hex Bolts: also known as hexagon head bolts or cap screws, have a hexagonal head that can be easily tightened or loosened with a wrench or socket. They are used in a wide range of applications and are available in various lengths and materials.

Carriage Bolts: Have a rounded, dome-shaped head and a square neck under the head. They are designed to prevent rotation when tightening and are often used in wood-to-metal connections.

Anchor Bolts: Embedded in concrete or masonry and are used to secure structural elements like columns, beams, and machinery to the foundation.

Stud Bolts: Have threads on both ends and are often used in conjunction with two nuts to secure flanges in piping systems.

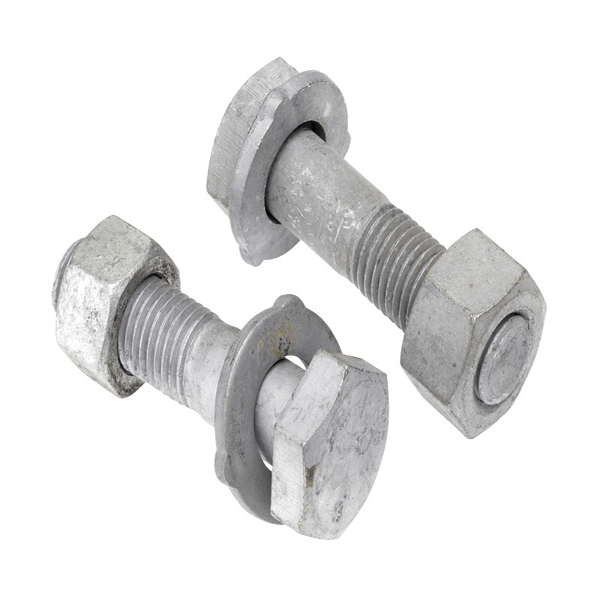

Flange Bolts: A flanged head that provides a wider load-bearing surface. They are often used in applications requiring a large bearing area.

These are just a few examples of the many types of bolts available. Each type of bolt is designed to serve specific purposes and offer unique features suited to different applications and industries. The choice of bolt type depends on factors such as load requirements, material compatibility, and the specific characteristics of the joint being fastened.

Specification:

| Product Name | Bolt |

| Diameter: | Metric: M6-M100 Imperial:1/4" to 4" |

| Length | Metric: Up to 800mm Imperial: Up to 30" |

| Material: | carbon steel, stainless steel (304 or 316), alloy steel, brass, and more |

| Strength Grade: | Metric: 800MPA/1000MPA/1200MPA Imperial: 125ksi/175ksi |

| Head Type: | Hex head/flange head/square head/heavy hex head/round head |

| Finish and Coating: | Black Oxide Coating/Zinc Plating (Electroplating)/Hot-Dip Galvanizing/Mechanical Galvanizing/Dacromet Coating/Painting or Powder Coating |

| Industry Standards: | ISO/ASTM/ASME/DIN/UNI/JIS |

| Packaging: | Boxes/cartons into wooden pallets |

| Application: | Construction/Agricultural Machinery/Industrial Structures/Equipment and Machinery/Infrastructure |

Regular Material of Bolts:

Steel Bolt Stainless Steel Bolts Brass Bolt Aluminum Bolt

Regular Dimension of Bolts:

M6 Bolt M8 Bolt M10 Bolt M12 Bolt M16 Bolt M20 Bolt M24 Bolt M30 Bolt M36 Bolt M42 Bolt M48 Bolt M56 Bolt M64 Bolt M72 Bolt M80 Bolt

- RELATED BOLTS LISTS:

- HEX BOLTS

- CARRIAGE BOLTS

- FLANGE BOLT

- HEAVY HEX BOLTS

- DIN931 HEX BOLTS

- AS1252 HEX BOLTS

- DIN6914 HEX BOLTS

- ASME B 18.2.1 HEX BOLTS

- A325 HEAVY HEX BOLTS

- A490 HEAVY HEX BOLTS

- ASME B 18.31.5 HRA Hook Bolts

- ASTM A394 HDG Tower Bolts

- ASTM A354 Hex Bolts

- ASME B 18.2.1 Square Head Bolts

- ASME/ANSI B 18.5 Round Head Square Neck Bolts

- ASME/ANSI B18.5 T- Head Bolts

- ASME/ANSI B18.2.1 Hex Head Flange Bolts

- ASME/ANSI B18.5 80°Slotted Countersunk Head Bolts

- ASME/ANSI B18.2.1 Hex Cap Bolts

- A307 Hex Head Bolts

- THREADED ROD LIST:

- DIN975 THREADED RODS

- A193 B7 STUD BOLTS

FAQ about bolts manufacturer:

1.How are bolts with specialized heads, such as carriage bolts, manufactured?

We choose the right production process according to different head shape/diameter/length/tolerance requirements. Diameter size is less than M24, length is less than 200mm, we will choose multi-station cold heading machine produce. Diameter size larger than M24, length larger than 200mm, we will choose hot forging.

2.Can you produce custom bolts to meet specific requirements?

Yes, we can customize bolts with specific dimensions, materials, coatings, or features to meet unique customer needs.

3.How to ensure traceability and quality assurance in bolt manufacturing?

We implement traceability systems, such as lot numbering, and maintain detailed records to ensure product quality and traceability.

4.Can you produce high-strength bolts for applications that require exceptional load-bearing capacity?

Yes, we can produce high-strength bolts with specific materials and heat treatments to meet the demands of heavy-duty applications like construction and aerospace.

5. What are the key steps in the quality assurance process for bolts during manufacturing?

Quality assurance involves inspections at various stages, including material testing, forging, threading, heat treatment, and surface finish checks.

6.What surface treatment bolts can you provide?

Regular surface treatment: Black/Plain Bolt Hot-Dip-Galvanized Bolt Galvanized/Zinc Plated Bolt

Manufacturer quality control in production process bolts:

In a world where connections matter, Ningbo Teng Qi Fasteners is more than just a bolts manufacturer and supplier. We are architects of stability, builders of relationships, and champions of your success. From skyscrapers that reach for the sky to machines that power industries, our hex bolts form the backbone of progress. When you choose Ningbo Teng Qi Fasteners, you choose unwavering quality, exceptional service, and a partner who understands that every bolt holds a piece of your vision.

| Control Method | Detail |

|---|---|

| Material Inspection: | Verify the material's composition, heat treatment, and quality upon receipt. Conduct metallurgical analysis to ensure the material properties meet the standards. |

| Process Control: | Implement strict process control measures for heat treatment, machining, threading, and any other manufacturing steps. Maintain consistent process parameters to ensure uniform quality. |

| Inspection Points: | Introduce inspection points at various stages of manufacturing to check for defects, dimensions, and quality. Inspect threading, dimensions, surface finish, and other critical parameters. |

| Sampling and Testing: | Regularly sample products for testing, such as tensile testing, hardness testing, and metallurgical analysis, to ensure they meet the required specifications. |

| Thread Inspection: | Thoroughly inspect threading using proper thread gauges to ensure accurate dimensions and fit with mating components. |

| Traceability: | Implement a traceability system to track each fasteners journey from raw material to final product. This aids in accountability and recalls if necessary. |