Eight Precautions For Construction Operations Of High-Strength Bolt Connections

In the construction organization and management of steel structure projects, there are many key links that affect the quality of the project, mainly in the construction operations of high-strength bolt connections. Whether high-strength bolt connections are constructed in accordance with specifications directly affects the quality of the entire steel structure project. This article explains how to proceed. The construction of high-strength bolt connections is explained in detail based on practical experience.

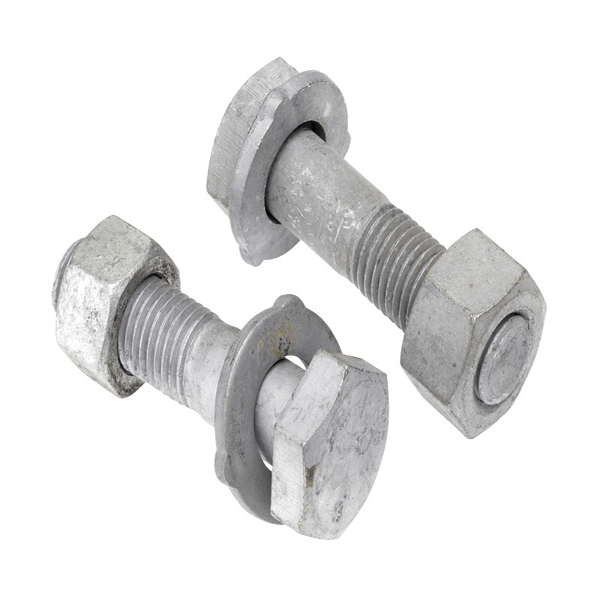

It is very common to use high-strength bolts to connect steel structures. This technology has the advantages of simple construction, intuitive inspection, reliable force, fast construction speed, good quality, and low cost. However, it has very strict requirements on construction technology and operation. If the construction is not paid enough attention, not only will it not be able to achieve a good connection effect , will also cause serious quality accidents. Now we will briefly describe the ten aspects of high-strength bolt connection construction technology and operational taboos, in order to attract the attention of construction operators and ensure the quality of steel structure projects.

1. Avoid using high-strength bolts as temporary installation bolts.

According to the construction regulations, when connecting and assembling, the installation bolts must be used first, that is, the holes should be aligned with a drill or a drill, and then temporary bolts with a number of not less than 1/3 of the street bolts should be inserted for center alignment of the structure. Tighten with a wrench, repair the holes, and then install high-strength bolts to ensure accurate bolt hole alignment and uniform axial force. In order to save trouble, some operators often omit the process of installing rough temporary bolts and directly use high-strength bolts instead of installing temporary bolts. Once fixed, they often cause incorrect alignment of the holes, or forcibly align the holes to make the connecting plates fit, and the bolts are not properly aligned. The threads are damaged, the torque coefficient changes, the bolt axial force is uneven, or the connecting plate generates internal stress, resulting in insufficient bolt pre-tightening force and reducing the connection strength.

2. Avoid high-strength bolts that cannot be installed and are forced into the holes.

The stress state of high-strength bolts is different from that of ordinary bolts. The former relies on the friction generated between connecting plates to transmit external force, while the latter transmits force through shearing of the bolts and extrusion of the hole wall. Therefore, when processing connecting plates, the hole requirements for high-strength bolts Drill into a right cylinder, with the surface of the hole wall perpendicular to the surface of the component, and the hole should be inserted according to regulations. The bolt should be able to penetrate the hole freely. The bolt hole should be 1-2 mm larger than the diameter of the bolt. If the hole is slightly small or double eyelids appear, use a reamer or electric drill to repair the hole, and then insert the high-strength bolt. Do not use a hammer to force the high-strength bolt into the hole. This will not only damage the threads, but also affect the pre-tightening effect. Moreover, the hole wall is squeezed and the bolt is sheared, which changes the stress state of the high-strength bolt and fails to play the role of the high-strength bolt. This is not allowed.

3. Avoid careless or no treatment of the friction surface.

The quality index of high-strength bolted joints is expressed by the friction coefficient. For example, the friction coefficient required for No. 3 steel is 0.45; the friction coefficient required for 20 manganese steel is 0.55. Therefore, before installing the connecting plate, the friction surface should be carefully treated, which is a necessary condition to ensure the transmission of stress. Rust on the fitting surface, welding gas cutting spatter, welding slag, dust, oil, bolt hole walls and plate edges Burrs and flash should be completely removed. Burrs and welding burrs on the edges of the hole wall plate and the plate surface should be ground off with a grinding wheel first, and then sandblasted. Do not reverse the procedure to damage the friction surface. The range of sandblasting or grinding should be no less than 4 times the diameter of the high-strength bolt. The grinding direction is perpendicular to the force direction. The friction surface after grinding should have no obvious unevenness. It is not allowed to be seriously eroded by rain for a long time after grinding. Some operators lack awareness of the importance of friction surface treatment, handle it sloppily, or even install it without treatment, causing interlayers between the friction surfaces, or sandblasting first and then grinding burrs and welding nodules, or failing to properly protect the friction surface and allowing it to corrode. , causing the friction surface to be concave and uneven, which will greatly reduce the friction surface coefficient and reduce the connection strength. In this case, the friction surface must be reprocessed to ensure quality.

4. Avoid gaps between connecting plates.

When installing high-strength bolts, due to sloppy and rough construction operations or operational defects, for example, when using a reamer to repair holes, the surrounding bolts are not tightened properly, causing iron filings to enter the friction surface, or the holes are not aligned correctly, and the connecting plate is installed. Then directly plug the hole with plug welding and re-drill, the welding slag squeezes into the seam of the plate, or the steel plate and steel section at the connection are warped and deformed, the bolt is installed without pre-correction, or there are burrs on the edge of the plate or hole, and there are debris between the plates. Installing bolts without thorough cleaning, or improper construction order, tightening from the outside to the middle of the bolt group, often causes the friction surfaces to not be in close contact, resulting in all or part of the gap between the friction surfaces, resulting in a decrease in the friction coefficient there Close to zero, the bolt cannot reach the specified pre-tightening axial force, which greatly reduces the connection strength and causes the connecting parts to slide after being stressed. In this case, if the gap is detected to be within 1 mm, no processing will be required. If the gap exceeds 2 mm, it must be reinstalled. If it cannot be corrected, it must be filled with wedge-shaped thin plates that have been treated with surface friction, and then install the bolts and make close contact to ensure the quality of the connection.

5. Avoid using screws, nuts and washers interchangeably.

The friction between the plates of high-strength bolted joints is determined by the pretightening force of the bolts and the friction coefficient between the joint surfaces. In order to ensure that the required pretightening force is achieved, the manufacturers have tested the nuts and washers of high-strength bolts to match each other so that The torque coefficient is a fixed value, and it is not allowed to mix the ones in different packages. At the same time, it is not allowed to be shaken and replayed to damage the threads, or be stained by mud, oil, or exposed to rain and moisture. When installing the remaining bolts, nuts, and washers on the same day, you must store the same number of matching bolts, and do not place them randomly or mix them with other accessories at will. Otherwise, the torque coefficient will change and the required pre-tightening force will not be achieved. Use When loosening the buckle, the pre-tightening force will be greatly reduced, which will affect the connection quality.

6. Avoid insufficient tightening torque or axial force.

In order to ensure the frictional force transmission of high-strength bolts, a certain torque is generally applied to the bolts to achieve the specified pretightening force in order to obtain the required connection strength. During installation, correction is often not performed due to faults or large errors in the electric or manual wrenches. Just use it, the torque is insufficient, or the connecting plate is uneven, the pre-tightening force is applied without correction, so that part of the torque value is consumed to overcome the deformation, or the operation is poor, the torque is reached on the wrench reading, but the actual pre-tightening force is not reached. Some bolts may be missing the initial or final tightening, causing uneven stress on the bolt group, or the final tightening does not reach the pre-tightening force axial force value required by the design. This will affect the pre-tightening force and reduce the connection strength. It should be used during operation. Pay attention to prevention.

7. Avoid tightening bolts all at once or not tightening them in the required order.

According to the construction regulations, in order to ensure uniform stress on each bolt between bolt groups and reduce the loss of axial force, bolt tightening should be performed in two steps; the first time, initial tightening should be performed to 60-80% of the standard bolt tension; Carry out final tightening for the second time and tighten to the standard pretensioning force, with the deviation not greater than 10%. Some operators try to be quick by tightening it all at once, or forgetting to tighten it initially. In this way, part of the axial force of the bolt is consumed in overcoming the deformation of the steel plate. When the bolts around it are tightened, the axial force is shared and reduced. . In addition, in order to ensure that all bolts in the bolt group are evenly stressed, the initial tightening and final tightening should be performed in a certain order. Generally, tightening should be done from the middle to the outside of the bolt group. Some operations are convenient, and the opposite order is adopted, starting from both sides. If the end to the middle is used, it often causes bulging in the middle, causing part of the axial force to be consumed in overcoming deformation, resulting in insufficient preload force and reduced friction coefficient, which affects the connection strength.

8. Avoid not fully tightening the bolts.

After the bolts are tightened according to regulations, the threads should be three buckles higher than the nut. However, sometimes due to ordering errors, the screw length is not enough, or because the steel material has a positive tolerance, or the steel plate is warped unevenly and has not been corrected, or the material is substituted and a thick strip is used. Thin, often causing the screw head to be lower than the nut. If the bolt is not replaced, it will be used improvised. This will make the nut easy to trip and loosen under long-term or vibration loads, reduce the pre-tightening force, and make the connection strength insufficient. It must be replace.