ISO4014 Hex Bolt Mamufacturer In China

Ningbo Teng Qi Fasteners stands as a leading ISO4014 half thread hex bolt manufacturer in China, equipped with multiple cold heading machines, hot forging machines, thread rolling machines, CNC turning machines, automatic chamfering machines, and two heat treatment production lines. With a rich production experience and mature production management, we have emerged as a key player in China’s bolt manufacturing industry. Our primary product, ISO4014, comes in various grades including 4.8, 8.8, 10.9, and 12.9. We supply ISO4014 bolts to numerous large companies in the power, oil, construction, heavy machinery, and chemical industries. The compelling reasons for customers to choose us include competitive pricing and stringent quality control.

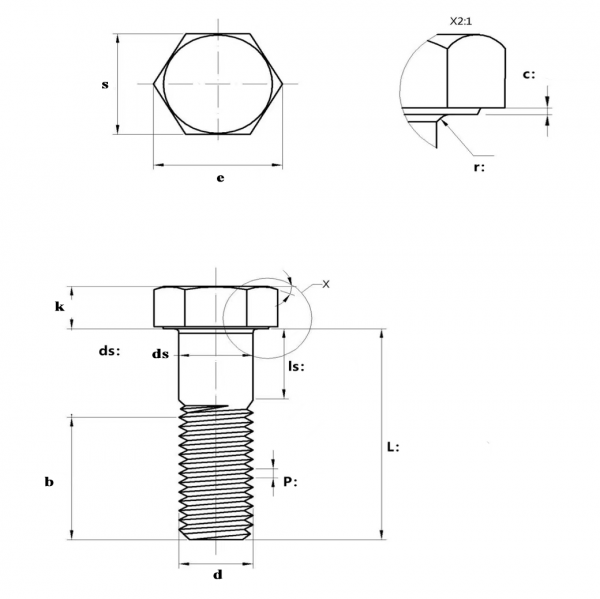

Specification:

ISO 4014 is a standard for hexagon head bolts with threads from M1.6 to M64. These bolts are typically made from carbon or alloy steel/stainless steel and are available in various strength grades. The specification includes details such as the dimensions, mechanical properties, and tolerances for these bolts.

For ISO 4014 hex bolts, some key specifications include:

| Product name | ISO4014 Hex Bolts |

|---|---|

| Thread | The thread of ISO 4014 hex bolts adheres to the ISO metric screw thread system. This system standardizes the pitch, diameter, and thread form of the bolts. The metric thread of ISO 4014 hex bolts is designed for precision and compatibility, ensuring uniformity in threading across various sizes. This standardized threading facilitates ease of use and interchangeability in different applications, providing a reliable and consistent fastening solution. |

| Length | The length of an ISO 4014 hex bolt is measured from the underside of the bolt head to the end of the threaded portion. It is important to choose the appropriate length based on the specific requirements of the application, ensuring that the bolt provides sufficient engagement for proper fastening while not exceeding the necessary length. |

| Head Type | Hexagonal head with six flat sides, designed for easy tightening with a wrench or socket. |

| Hardness | Class4.8: 130-220HV Class8.8: d≤M16 22-32HRC Class8.8: d>M16 23-34HRC Class10.9: 32-39HRC Class12.9: 39-44HRC |

| Class | Class4.8/8.8/10.9/12.9 A2-70 A2-80 A4-70 A4-80 A4-100 |

| Material | The DIN standard allows for the manufacture of these hex bolts using various materials, including but not limited to: - Carbon steel - Alloy steel - Stainless steel |

| Surface treatment | The standard specifies surface finishes to enhance corrosion resistance and appearance. Common finishes include: - Plain (uncoated) - Zinc plating - Hot-dip galvanizing - Other corrosion-resistant coatings |

- RELATED BOLTS LISTS:

- HEX BOLTS

- HEAVY HEX BOLTS

- DIN931 HEX BOLTS

- DIN933 HEX BOLTS

- ISO4017 HEX BOLTS

- AS1252 HEX BOLTS

- DIN6914 HEX BOLTS

- ASME B 18.2.1 HEX BOLTS

- A325 HEAVY HEX BOLTS

- A490 HEAVY HEX BOLTS

- RELATED NUTS LIST:

- HEX NUTS

- HEAVY HEX NUTS

- ISO4032 HEX NUTS

- DIN934 HEX NUTS

- A194 HEAVY HEX NUTS

- A563 HEAVY HEX NUTS

- THREADED ROD LIST:

- DIN975 THREADED RODS

- A193 B7 STUD BOLTS

Dimension Chart of ISO4014:

The ISO 4014 standard covers hexagon head bolts with various dimensions. Here are some key details:

1. Thread Size: The standard includes a range of thread sizes from M1.6 to M64, indicating the diameter and pitch of the threads.

2. Across Flats of Hex Head: This dimension represents the distance across opposite flat surfaces of the hexagonal head, providing the wrench size required for tightening.

3. Across Corner: This dimension is the distance across the sharp corners of the hexagonal head and is larger than the across flats measurement.

4. Head Thickness: Refers to the thickness of the hexagonal head.

5. Round Radius: This pertains to the curvature at the transition between the head and the shank of the bolt.

| Thread Diameter(d) | Thread Pitch(P) | Width Across Flat (s) | Width Across Corner(e) Min | Head Height (k) | Radius(r) Min | Washer Face Thickness(c) | Thread Length(b) L≤125 | Thread Length(b) 125<L≤200 | Thread Length(b) L>200 |

| M1.6 | 0.35 | 3.02-3.2 | 3.41 | 0.98-1.22 | 0.1 | 0.1-0.25 | 9 | - | - |

| M2 | 0.4 | 3.82-4 | 4.32 | 1.28-1.52 | 0.1 | 0.1-0.25 | 10 | - | - |

| M3 | 0.5 | 5.32-5.5 | 6.01 | 1.88-2.12 | 0.1 | 0.15-0.4 | 12 | - | - |

| M4 | 0.7 | 6.64-7 | 7.5 | 2.6-3 | 0.2 | 0.15-0.4 | 14 | - | - |

| M5 | 0.8 | 7.64-7.78 | 8.63 | 3.26-3.74 | 0.2 | 0.15-0.5 | 16 | 22 | - |

| M6 | 1 | 9.64-10 | 10.89 | 3.76-4.24 | 0.25 | 0.15-0.5 | 18 | 24 | - |

| M8 | 1.25 | 12.57-12.73 | 14.2 | 5.06-5.54 | 0.4 | 0.15-0.6 | 22 | 28 | - |

| M10 | 1.5 | 15.57-16 | 17.59 | 6.11-6.69 | 0.4 | 0.15-0.6 | 26 | 32 | 45 |

| M12 | 1.75 | 17.57-18 | 19.85 | 7.21-7.79 | 0.6 | 0.15-0.6 | 30 | 36 | 49 |

| M14 | 2 | 20.16-21 | 22.78 | 8.51-9.09 | 0.6 | 0.15-0.6 | 34 | 40 | 53 |

| M16 | 2 | 23.16-23.67 | 26.17 | 9.71-10.29 | 0.6 | 0.2-0.8 | 38 | 44 | 57 |

| M18 | 2.5 | 26.15-26.67 | 29.56 | 11.15-11.85 | 0.6 | 0.2-0.8 | 42 | 48 | 61 |

| M20 | 2.5 | 29.16-29.67 | 32.95 | 12.15-12.85 | 0.8 | 0.2-0.8 | 46 | 52 | 65 |

| M22 | 2.5 | 33-34 | 37.29 | 13.65-14.35 | 0.8 | 0.2-0.8 | 50 | 56 | 69 |

| M24 | 3 | 35-36 | 39.55 | 14.65-15.35 | 0.8 | 0.2-0.8 | 54 | 60 | 73 |

| M27 | 3 | 40-41 | 45.2 | 16.65-17.35 | 1 | 0.2-0.8 | 60 | 66 | 79 |

| M30 | 3.5 | 45-46 | 50.85 | 18.28-19.12 | 1 | 0.2-0.8 | 66 | 72 | 85 |

| M33 | 3.5 | 49-50 | 55.37 | 20.58-21.42 | 1 | 0.2-0.8 | 72 | 78 | 91 |

| M36 | 4 | 53.8-55 | 60.79 | 22.08-22.92 | 1 | 0.2-0.8 | 78 | 84 | 97 |

| M39 | 4 | 58.8-60 | 66.44 | 24.58-25.42 | 1 | 0.3-1 | 84 | 90 | 103 |

| M42 | 4.5 | 63.1-65 | 71.3 | 25.58-26.42 | 1.2 | 0.3-1 | 90 | 96 | 109 |

| M45 | 4.5 | 68.1-70 | 76.95 | 27.58-28.42 | 1.2 | 0.3-1 | 96 | 102 | 115 |

| M48 | 5 | 73.1-75 | 82.6 | 29.58-30.42 | 1.6 | 0.3-1 | 102 | 108 | 121 |

| M52 | 5 | 78.1-80 | 88.25 | 32.5-33.5 | 1.6 | 0.3-1 | - | 116 | 129 |

| M56 | 5.5 | 82.8-85 | 93.56 | 34.5-35.5 | 2 | 1 max | - | 124 | 137 |

| M64 | 6 | 92.8-95 | 104.86 | 39.5-40.5 | 2 | 1 max | - | 132 | 145 |

| M72 | 6 | 102.8-105 | 116.16 | 44.5-45.5 | 2 | 1 max | - | 156 | 169 |

Application of ISO4014 Bolts:

The applications of ISO 4014 hex bolts in different industries:

| Application | Details |

|---|---|

| Construction Industry: | Applications: Connecting steel beams, securing construction elements, assembling structural components. Sizes: M12 - M64 Classes: 8.8 and 10.9 for ensuring structural integrity in various construction projects. |

| Machinery and Manufacturing: | Applications: Machinery assembly, fastening different parts of equipment. Sizes: M6 - M36 Classes: 8.8 and 10.9 for reliable and secure fastening in the manufacturing process. |

| Automotive Industry: | A325 bolts are used in the assembly of communication towers, electrical transmission towers, and other tall structures. They provide a secure fastening method for connecting tower sections and maintaining stability. |

| Railway Infrastructure: | Applications: Securing tracks, connecting rail components, assembling railway structures. Sizes: M16 - M36 Classes: 8.8 and 10.9 for robust connections in the railway industry. |

| Aerospace Engineering: | Applications: Assembly of aircraft components. Sizes: M6 - M24 Classes: 10.9 and 12.9 for meeting high-strength requirements in critical aerospace applications. |

| Industrial Equipment: | Applications: Fastening and securing components in various manufacturing processes. Sizes: M6 - M36 Classes: 8.8 and 10.9 for general industrial applications ensuring reliability. |

| Renewable Energy: | Applications: Construction of wind turbines, solar panels, and related infrastructure. Sizes: M12 - M36 Classes: 8.8 and 10.9 for durability and stability in renewable energy projects. |

| Electronics Manufacturing: | Applications: Assembly of electronic devices and equipment. Sizes: M1.6 - M6 Classes: 4.6 and 8.8 for precise fastening in electronic components. |

| Oil and Gas: | Applications: Construction and maintenance of facilities, pipelines. Sizes: M16 - M36 Classes: 8.8 and 10.9 for strength and corrosion resistance in demanding oil and gas environments. |

FAQ about ISO4014 Hex Bolts:

1.What is the pricing for class 8.8 ISO4014 hex bolts?

Typically, our class 8.8 ISO4014 hex bolts are manufactured from C45 steel. The pricing encompasses materials, processing, packaging, and labor costs. We operate as a bolt manufacturing facility, primarily catering to wholesalers and distributors. Our commitment is to ensure our customers’ profitability. The wholesale price range for class 8.8 bolts falls between approximately 1300-2000 USD per ton. Steel material prices are subject to frequent fluctuations, and the price varies depending on surface treatment and quantity. For specific pricing inquiries, please contact us via email: Email: info@china-bolts.com

2. What is the usual lead time for delivering a container of bolts?

Our daily production capacity for cold heading and hot forging bolts is roughly 30 tons. However, due to factors such as material preparation, heat treatment, surface treatment, and order scheduling, it does require some time. On average, the delivery time for a container of bolts typically falls within the range of 30-40 days.

3. Can you guarantee the quality of these bolts?

Absolutely. From the selection of raw materials to the final packaging, we maintain stringent quality control measures. We understand that there may be concerns regarding the quality of Chinese fasteners. Nevertheless, we can confidently affirm that our fasteners meet performance requirements, and we maintain traceable records of the materials used.

4. Are samples available for ISO4014 bolts?

Certainly, we maintain a stock of bolts in standard sizes, and we can provide samples free of charge. However, please note that the customer is responsible for covering the freight costs.

5. Is there a minimum order quantity (MOQ) requirement?

Yes, our standard MOQ is approximately one ton. However, for items in our inventory, we can supply even smaller quantities, starting from as low as 10 units.

6. Which countries do you export your bolts to?

Over the course of more than a decade, we have cultivated stable relationships with customers in various countries. These include the United States, Germany, Russia, Poland, Spain, Brazil, Argentina, Vietnam, Canada, Australia, the UAE, Saudi Arabia, and more.

Manufacturing Quality Control of ISO4014 hex bolts:

| Control Method | Detail |

|---|---|

| Material Inspection: | Verify the material's composition, heat treatment, and quality upon receipt. Conduct metallurgical analysis to ensure the material properties meet the standards. |

| Process Control: | Implement strict process control measures for heat treatment, machining, threading, and any other manufacturing steps. Maintain consistent process parameters to ensure uniform quality. |

| Inspection Points: | Introduce inspection points at various stages of manufacturing to check for defects, dimensions, and quality. Inspect threading, dimensions, surface finish, and other critical parameters. |

| Sampling and Testing: | Regularly sample products for testing, such as tensile testing, hardness testing, and metallurgical analysis, to ensure they meet the required specifications. |

| Thread Inspection: | Thoroughly inspect threading using proper thread gauges to ensure accurate dimensions and fit with mating components. |

| Traceability: | Implement a traceability system to track each fasteners journey from raw material to final product. This aids in accountability and recalls if necessary. |