ISO4032 Hex Nuts Manufacturer In China

Ningbo Teng Qi Fasteners Co., Ltd is a leading iso4032 hex nuts manufacturer in China. ISO4032 is an international standard that specifies the dimensions and technical requirements for hexagon nuts, including those with a heavy hex pattern. ISO4032 hex nuts are designed to be used with bolts and screws of corresponding property classes and thread sizes. They are commonly used in various industries and applications to secure components together. The standard defines the dimensions, tolerances, and materials for these nuts, ensuring interchangeability and compatibility with other ISO standardized components.

Specification of ISO4032 Hex Nut:

The ISO 4032 standard specifies the characteristics of hex regular nuts, with threads from M1.6 to M64. Here are some key specifications for ISO 4032 hex nuts:

| Product name | ISO4032 Hex Nuts |

|---|---|

| Thread Diameter: | The thread diameter is the nominal diameter of the threaded section of the nut and is typically expressed in millimeters. For example, a notation for a thread specification might look like M12 x 1.75, where: - "M" stands for metric, - "12" is the nominal diameter of the thread in millimeters, and - "1.75" is the pitch of the thread in millimeters. |

| Thread Pitch: | The thread pitch is the distance between adjacent threads and is specified in millimeters. Different sizes of ISO 4032 hex nuts will have different thread pitches. |

| Class | 5/8/10/12 |

| Hardness | Class5: 130-302HV (M8×1 ≤ D ≤ M16×1,5) 146-302HV (M16 < D ≤ M39) Class8: 200-302HV (M8×1 ≤ D ≤ M16×1,5) 233-302HV (M16 < D ≤ M39) Class10: 272-353HV (M8×1 ≤ D ≤ M39) Class12: 295-302HV (M8×1 ≤ D ≤ M16×1,5) 272-302HV (M16 < D ≤ M39) |

| Material | ISO 4032 hex nuts can be made from various materials, including carbon steel, stainless steel, and other alloys. The specific material should conform to the relevant material standards. |

| Manufacturing Process | wire drawing, cold heading/hot forging, thread rolling, heat treatment, surface treatment |

| Surface treatment | ISO 4032 hex nuts may have specific requirements for surface finish, which can include treatments like Black Oxide Coating/Zinc Plating (Electroplating)/Hot-Dip Galvanizing/Mechanical Galvanizing/Dacromet Coating/Painting or Powder Coating. |

| Application Industry | Construction/Machinery/Automotive/Infrastructure/Electrical and Electronics/Furniture/Marine and Offshore |

Comparison of ISO4032 and DIN934:

1. Hardness/Proof load

Nuts DIN 934 and ISO 4032 performance grades are the same.

2. Nut thickness

The thickness of ISO 4032 hex nuts is higher than DIN 934 hex nuts for the same nominal thread diameter.

3. The standards of different countries

DIN 934 is the German standard and ISO 4032 is the ISO international standard.

Dimension Chart of ISO4032:

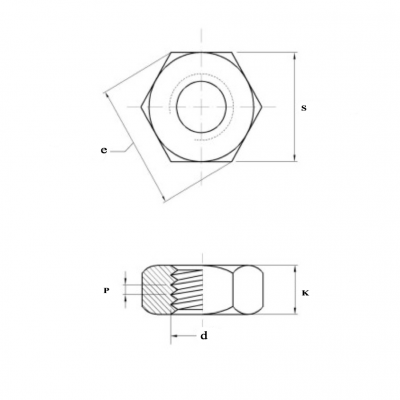

Here are the explains for the dimensions of thread diameter, width across flats, and thickness for ISO 4032 hex nuts:

1. Thread Diameter (Nominal Diameter): This refers to the nominal diameter of the threaded section of the nut. For example, in the notation M12 x 1.75, “M12” represents a metric thread with a nominal diameter of 12 millimeters. It is the diameter of the imaginary cylinder that would pass through the threads.

2. Width Across Flats (WAF): This is the distance between two opposite flat surfaces of the hex nut. It is essentially the width of the nut when measured across its flats. For example, in the table, for an M12 hex nut, the width across flats is 19 millimeters.

3. Thickness: The thickness is the distance between the bearing surface (the surface in contact with the assembly) and the opposite surface of the nut. For example, in the table, for an M12 hex nut, the thickness is 12 millimeters.

These dimensions are crucial for selecting the right hex nut for a specific application, ensuring compatibility with bolts or screws, and determining how well the nut will fit into a particular assembly.

| Thread Diameter(d) | Thread Pitch(P) | Width Across Flat (s) | Width Across Corner(e) Min | Height (k) |

| M1.6 | 0.35 | 3.02-3.2 | 3.41 | 1.05-1.3 |

| M2 | 0.4 | 3.82-4 | 4.32 | 1.35-1.6 |

| M3 | 0.5 | 5.32-5.5 | 6.01 | 2.15-2.4 |

| M4 | 0.7 | 6.64-7 | 7.5 | 2.9-3.2 |

| M5 | 0.8 | 7.64-7.78 | 8.63 | 4.4-4.7 |

| M6 | 1 | 9.64-10 | 10.89 | 4.9-5.2 |

| M8 | 1.25 | 12.57-12.73 | 14.2 | 6.44-6.8 |

| M10 | 1.5 | 16.57-16.73 | 18.72 | 8.04-8.4 |

| M12 | 1.75 | 18.48-19 | 20.88 | 10.37-10.8 |

| M14 | 2 | 21.16-21.67 | 23.91 | 12.1-12.8 |

| M16 | 2 | 23.16-23.67 | 26.17 | 14.1-14.8 |

| M18 | 2.5 | 26.15-26.67 | 29.56 | 15.1-15.8 |

| M20 | 2.5 | 29.16-29.67 | 32.95 | 16.9-18 |

| M22 | 2.5 | 31-32 | 35.03 | 18.1-19 |

| M24 | 3 | 35-36 | 39.55 | 20.2-21.5 |

| M27 | 3 | 40-41 | 45.2 | 22.5-23.8 |

| M30 | 3.5 | 45-46 | 50.85 | 24.3-25.6 |

| M33 | 3.5 | 49-50 | 55.37 | 27.4-28.7 |

| M36 | 4 | 53.8-55 | 60.79 | 29.4-31 |

| M39 | 4 | 58.8-60 | 66.44 | 31.8-33.4 |

| M42 | 4.5 | 63.1-65 | 71.3 | 32.4-34 |

| M45 | 4.5 | 68.1-70 | 76.95 | 34.4-36 |

| M48 | 5 | 73.1-75 | 82.6 | 36.4-38 |

| M52 | 5 | 78.1-80 | 88.25 | 40.4-42 |

Application of ISO4032 Nuts:

ISO 4032 hex nuts, being a standard for general-purpose hexagon nuts, find application in various industries and scenarios where metric fasteners are required. Some common applications include:

| Application | Details |

|---|---|

| General Construction: | SO 4032 hex nuts are widely used in general construction applications, such as assembling steel structures, bridges, and buildings. Their standardized metric threads make them suitable for a range of construction projects. |

| Machinery and Equipment: | These hex nuts are utilized in the assembly of machinery and equipment across different industries. The metric thread sizes cater to the needs of diverse mechanical applications. |

| Automotive: | ISO 4032 hex nuts can be found in automotive manufacturing and repair. They may be used in components like engines, chassis, and other parts where metric fasteners are specified. |

| Railroad Infrastructure: | In the construction and maintenance of railroad tracks and infrastructure, ISO 4032 hex nuts are employed to secure various components due to their standardized metric design. |

| Manufacturing and Industrial Settings: | These hex nuts are used in various manufacturing processes and industrial applications where metric fasteners are required for reliable and secure fastening. |

| Electronics: | In certain electronic applications where metric fasteners are specified, ISO 4032 hex nuts may be used for securing components. |

| Oil and Gas Applications: | Used in the assembly and maintenance of equipment within the oil and gas industry, supporting the extraction, processing, and transportation processes. |

| Renewable Energy Projects: | Applied in the construction and maintenance of renewable energy infrastructure, including wind turbines and solar panel installations. |

| Energy and Power Generation: | Hex nuts are used in energy facilities, including power plants and renewable energy installations, to secure equipment and structures. |

| Marine and Shipbuilding: | The marine industry relies on hex nuts for fastening components in ships, boats, offshore structures, and maritime equipment. |

| Mining and Heavy Equipment: | Hex nuts are used in mining equipment and heavy machinery, ensuring that connections remain secure in harsh operating environments. |

Quality control of ISO4032 Nuts:

| Control Method | Detail |

|---|---|

| Material Inspection: | Verify the material's composition, heat treatment, and quality upon receipt. Conduct metallurgical analysis to ensure the material properties meet the standards. |

| Process Control: | Implement strict process control measures for heat treatment, machining, threading, and any other manufacturing steps. Maintain consistent process parameters to ensure uniform quality. |

| Inspection Points: | Introduce inspection points at various stages of manufacturing to check for defects, dimensions, and quality. Inspect threading, dimensions, surface finish, and other critical parameters. |

| Sampling and Testing: | Regularly sample products for testing, such as tensile testing, hardness testing, and metallurgical analysis, to ensure they meet the required specifications. |

| Thread Inspection: | Thoroughly inspect threading using proper thread gauges to ensure accurate dimensions and fit with mating components. |

| Traceability: | Implement a traceability system to track each fasteners journey from raw material to final product. This aids in accountability and recalls if necessary. |