Lock Nuts Manufacturer in China

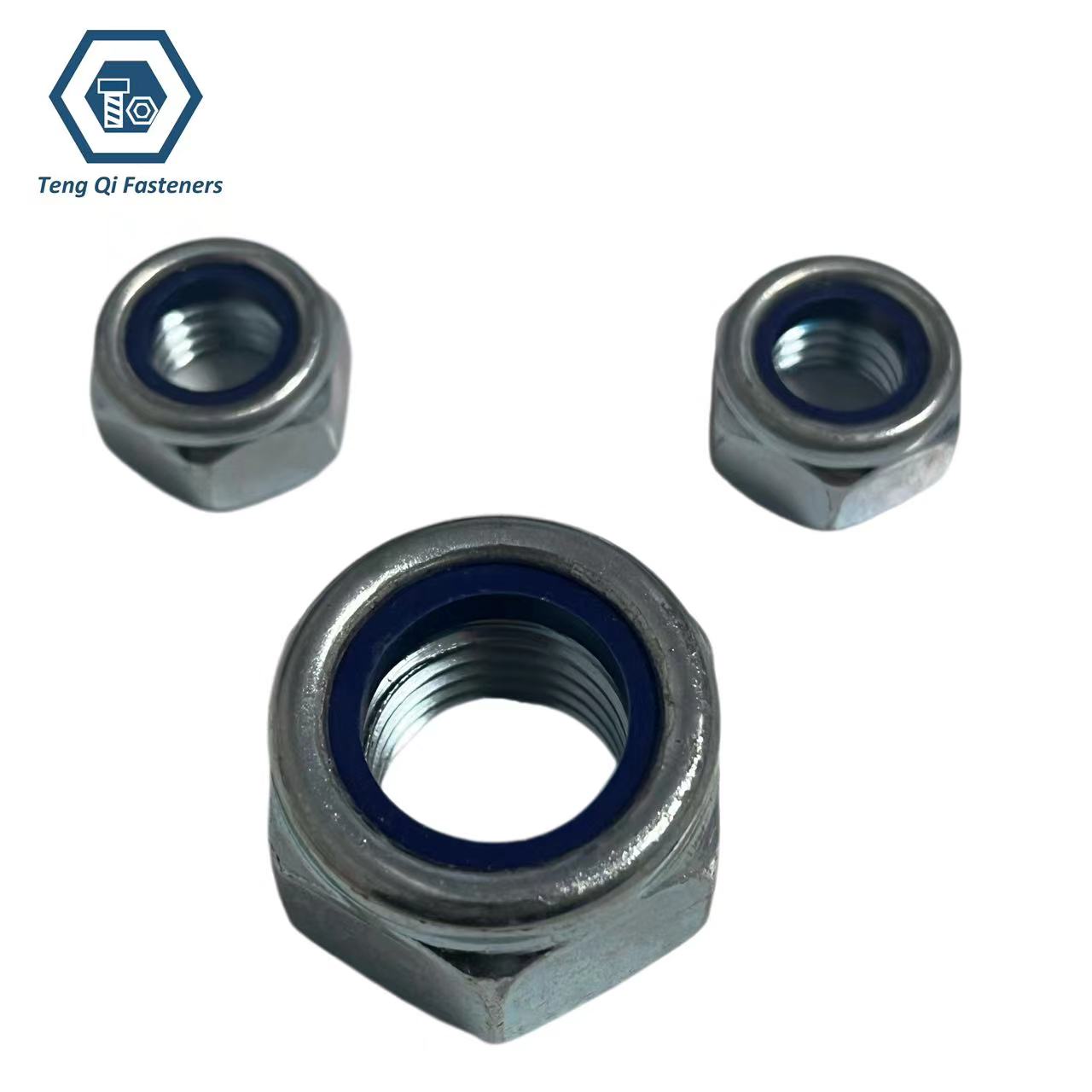

Ningbo Teng Qi Fasteners Co., Ltd is a leading lock nuts manufacturer in China. Lock nut, also known as locking nuts or prevailing torque nuts, are a type of nut designed to resist loosening due to vibration, temperature fluctuations, or other external forces. They provide an extra level of security to threaded connections by adding a locking mechanism that prevents the nut from coming loose unintentionally.

Feature of lock nuts:

| Locking Mechanism: | Lock nuts incorporate a locking feature that increases the friction or tension on the threads, making it harder for the nut to rotate freely |

| Prevailing Torque: | The prevailing torque is the resistance encountered when tightening or loosening the lock nut. This resistance is deliberately added to prevent the nut from loosening on its own. |

| Types of Locking Mechanisms: | There are several types of locking mechanisms used in lock nuts, including nylon inserts, deformed threads, serrated flanges, and metal inserts. These mechanisms create additional resistance or interference to prevent self-loosening. |

| Applications: | Lock nuts are used in applications where vibration, movement, or changes in temperature could potentially cause traditional nuts to come loose. |

Specification of Lock Nuts:

Lock nuts find applications in situations where preventing the unintentional loosening of threaded connections is crucial. They offer added security to fasteners exposed to vibrations, temperature fluctuations, or dynamic loads.

Lock nut are selected based on factors such as the type of locking mechanism, prevailing torque, material compatibility, and specific environmental conditions. Their ability to maintain secure connections in challenging circumstances makes them indispensable components across a wide range of industries.

| Product name | Lock Nuts |

| Type of lock nuts | Nylon Insert Lock Nuts Serrated Flange Lock Nuts All Metal Lock Nuts |

| Diameter | Metric: M3-M48 Imperial:2#-2” |

| Class | 5/8/10/12 A2-70 A2-80 A4-70 A4-80 |

| Grade | SAE J995 GR.2/5/8 |

| Material | Steel/Stainless steel/Brass/Aluminum |

| Manufacturing Process | wire drawing, cold heading/hot forging, thread rolling, heat treatment, surface treatment |

| Surface treatment | Black Oxide Coating/Zinc Plating (Electroplating)/Hot-Dip Galvanizing/Mechanical Galvanizing/Dacromet Coating/Painting or Powder Coating |

| Application Industry | Construction/Agricultural Machinery/Industrial Structures/Equipment and Machinery/Infrastructure/Mechanical and Engineering/Automotive and Transportation |

Manufacturing Quality Control of lock nut:

| Control Method | Detail |

|---|---|

| Material Inspection: | Verify the material's composition, heat treatment, and quality upon receipt. Conduct metallurgical analysis to ensure the material properties meet the standards. |

| Process Control: | Implement strict process control measures for heat treatment, machining, threading, and any other manufacturing steps. Maintain consistent process parameters to ensure uniform quality. |

| Inspection Points: | Introduce inspection points at various stages of manufacturing to check for defects, dimensions, and quality. Inspect threading, dimensions, surface finish, and other critical parameters. |

| Sampling and Testing: | Regularly sample products for testing, such as tensile testing, hardness testing, and metallurgical analysis, to ensure they meet the required specifications. |

| Thread Inspection: | Thoroughly inspect threading using proper thread gauges to ensure accurate dimensions and fit with mating components. |

| Traceability: | Implement a traceability system to track each fasteners journey from raw material to final product. This aids in accountability and recalls if necessary. |