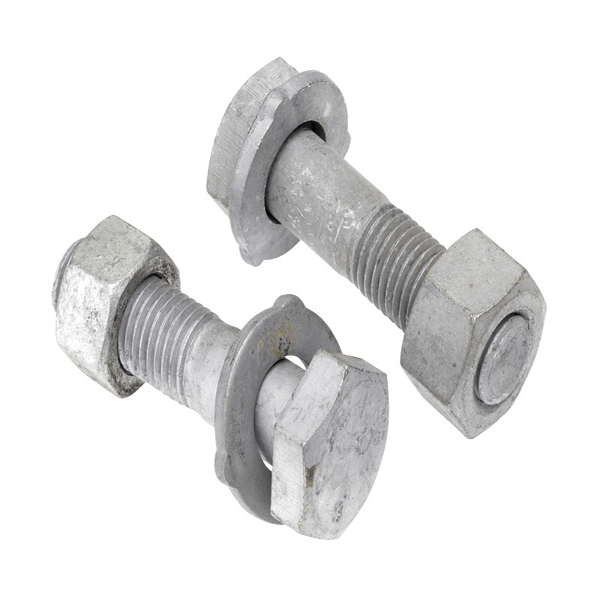

Steel Structure Engineering Must Master These Coefficients and Torques

Several key points in the installation of steel structures, friction coefficient, torque coefficient, initial tightening torque, and final tightening torque. These are very important points when installing steel structures. It will affect the installation quality of the steel structure, so these points must be understood.

1. Torque coefficient:

where d is the nominal diameter of the high-strength bolt (mm), M is the applied torque value (N﹒M), and P is the bolt pretightening force. Class 10.9 high-strength large hexagonal bolt connections must ensure that the average torque coefficient K is 0.110 to 0.150. Its standard deviation should be less than or equal to 0.010.

2. Initial tightening torque:

In order to reduce the influence of steel plate deformation during bolt tightening, secondary tightening can be used to reduce the mutual influence between successively tightened bolts. The first tightening of high-strength bolts is the initial tightening, so that the axial force should reach 60% to 80% of the standard axial force.

3. Final tightening torque:

The final tightening torque of high-strength bolts is the final tightening torque. Considering the losses of various prestresses, the final twisting torque is generally 5% to 10% greater than the theoretically calculated torque value based on the design pretensioning force.

4. Friction coefficient:

where F is the force causing initial slip of the specimen measured in the anti-slip test, nf is the number of friction surfaces, and is the sum of the measured values of the high-strength bolt tightening pretension force corresponding to F.